Perfect Designs for Harsh Conditions

Fabric expansion joints are flexible components designed to absorb thermal expansion, vibrations, and movements in industrial piping systems. Fabric expansion joints are ideal for handling high temperature variations and chemical environments. They are commonly used in power plants, boiler systems, exhaust lines, and gas turbines.

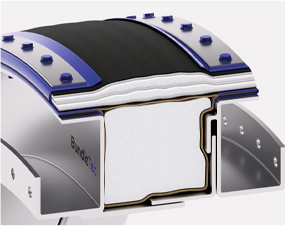

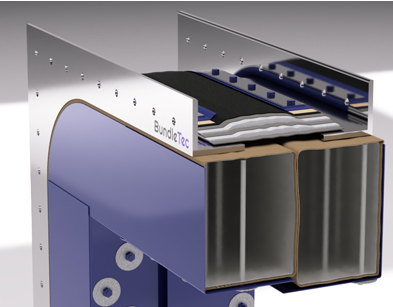

Fabric expansion joints stand out with their multi-layered structure: an outer protective layer, thermal insulation layers, and an inner support layer. These layers provide resistance to various temperature ranges, pressure levels, and chemical substances. They protect pipelines and equipment, enhancing system reliability and preventing damage from vibrations and impacts.

At BundleTec, we offer customized fabric expansion joint solutions for every project. Our products ensure long-lasting performance in demanding industrial conditions and are compatible with existing systems. Our expert team develops tailored designs to meet your specific needs.

Advantages of Fabric Expansion Joints

Flexibility

Absorbs thermal expansion and vibrations, enhancing system reliability.

Durability

Layers resistant to chemicals and high temperatures.

Lightweight

Lighter than metal alternatives, offering easy installation solutions.

Customization

Tailored designs for perfect compatibility with your project.

Frequently Asked Questions

What materials are fabric expansion joints made of?

Typically made of high-temperature-resistant fabrics, silicone, PTFE, and insulation layers, customized for the project.

What are the applications of fabric expansion joints?

Widely used in power plants, gas turbines, exhaust systems, boilers, and chemical plants.

How to choose fabric expansion joints?

Selection is made with our experts, considering factors like temperature, pressure, chemical environment, and movement type.