Rectangular Lens Metal Expansion Joints – High Durability and Long Cycle Life

Rectangular Lens Metal Expansion Joints – High Durability and Long Cycle Life

CUSTOMER REQUIREMENT

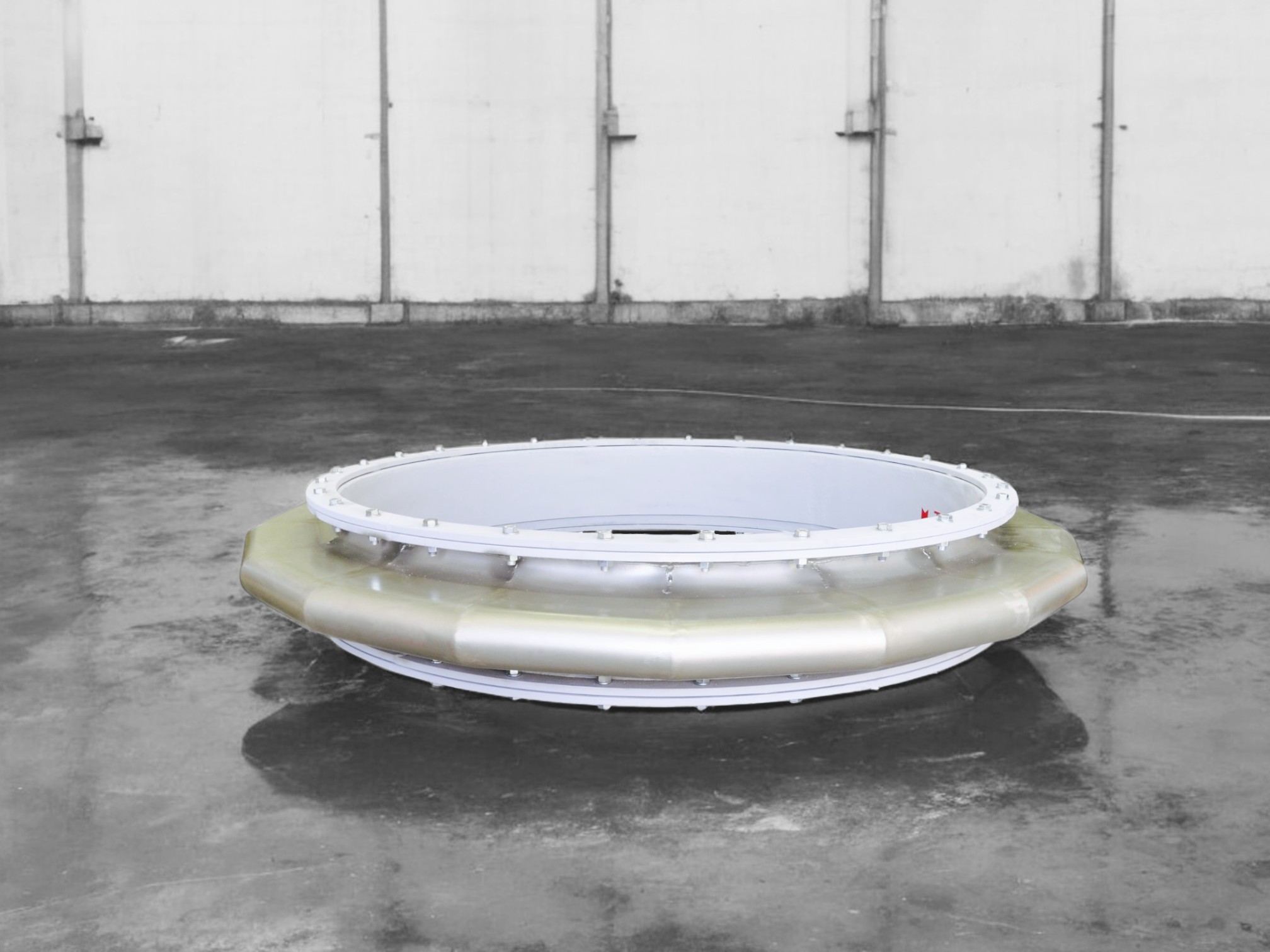

The durability and long-lasting performance of industrial systems depend on specially designed expansion joints that can effectively absorb thermal expansion. In this context, rectangular lens metal expansion joints with 1500x900 mm flange dimensions and radiused corner design were manufactured according to customer demands. This design stands out particularly in projects with high cycle life expectations.

SOLUTION – Rectangular Expansion Joint Design with High Cycle Life

These expansion joints manufactured from 16Mo3 (1.5415) grade steel sheet offer long cycle life even under the most challenging operating conditions thanks to their radiused corner design. The special shaping of corners minimizes stress accumulation and increases the durability of lens bellows. This ensures that expansion joints serve for long periods without deformation.

The interior of lens bellows is filled with high temperature resistant insulation material, reducing the negative effects that heat can create on metal. The insulation both prevents temperature-related performance loss of the expansion joint and extends cycle life. This special design stands out as one of the most durable and long-lasting options among rectangular lens metal expansion joints.

These expansion joints were designed for use in the Hot Air Branching Duct to Combustion Chamber section in thermal power plants. This section is a critical working area that requires effective management of both high temperature and mechanical movements. The expansion joints were manufactured to withstand these challenging conditions and fully met customer expectations.